Strainers are widely used in industrial installations. They often filter out coarser particles from liquids or gases and thereby protect important components such as pumps, heat exchangers, and other appendages. In this blog, we explain what strainers are, how they work, what types there are, and what benefits they can offer for your processes.

What are strainers?

A strainer is a filter element designed to remove (coarse) solid particles, sediment, or other impurities from liquids or gases. In industrial systems, a strainer protects vulnerable components from clogging or damage, and helps to keep the process efficient and trouble-free. Strainers have a low pressure drop and are usually placed in the suction of a pump. The low pressure drop prevents cavitation in a pump and protects the impellers.

By capturing coarse particles, strainers prolong the lifespan of installations and appendages and keep operational costs better controlled.

What types of strainers are there?

There are different types of strainers suitable for various applications, depending on the type of system and the flow rate. The most commonly used types are:

- Y-strainers: Compact in size, suitable for applications with lower flow rates or limited space.

- T-strainers: Provide a larger filtering area and are often used in higher flow rates in, for example, cooling and heating installations.

- Basket strainers: Designed for systems with larger capacities. The basket-shaped sieve captures larger amounts of contamination and is easy to clean.

- Duplex strainers: Basket strainer, double execution no interruptions, never stop again!

- Automated self-cleaning strainers: Motorized units designed for continuous removal of (coarse) particles from liquids.

How does a strainer work?

A strainer allows a liquid or gas to flow through a sieve or perforated element. Solid particles remain in the filter, while the clean liquid or gas can continue to flow through. This prevents damage or clogs in the system.

Strainers are easy to install in piping systems and require relatively little maintenance.

Fineness of a strainer

Three terms are used with strainers to indicate the fineness of the filter:

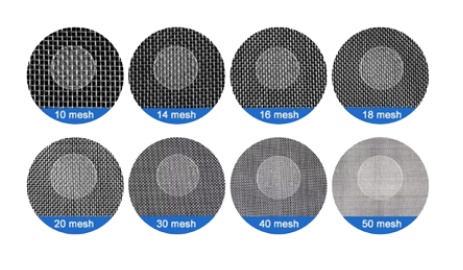

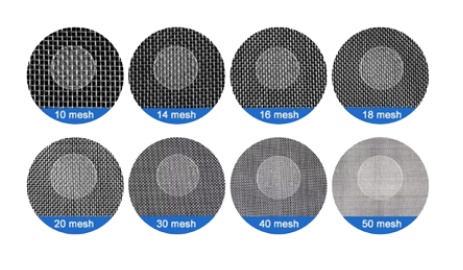

- Mesh: The number of openings per inch. The higher the number, the finer the filter. For example, a 20 mesh sieve has 20 openings per inch.

- Perf: Abbreviation for perforation. This refers to the diameter of the holes in the filter, for example 0.062” (1/16”).

- Diameter: Sometimes this term is used as an alternative to perf, in millimeters or inches.

The correct filter size depends on the type of contamination and the application.

Where are strainers used?

Strainers are used in a wide range of industrial applications. From water treatment systems to oil processing installations. They are used in:

- Pump and piping systems: To protect pumps, valves, and pipes from contamination.

- Heat exchangers: To prevent dirt deposits and keep heat transfer efficient.

- Cooling systems: To ensure stable operation of the process.

- Water and wastewater treatment: To remove solid particles from water flows.

- Other process installations: To prevent equipment damage and ensure process quality.

What are the benefits of using the right strainer?

Strainers contribute in various ways to the reliability and efficiency of your installation:

- Protection of systems: They help prevent damage to installations.

- Reduced unplanned downtime: Clogs are prevented, increasing operational reliability.

- Lower maintenance and repair costs: By filtering out impurities, wear is limited.

- Durable and maintenance-friendly: Many strainers are robustly designed and easy to clean or replace.

Interfilter provides custom strainers

Interfilter offers a wide range of strainers and filter baskets for various industrial applications. We deliver both standard products and customized solutions, tailored to your specific system and requirements. View our range here.

Need advice without obligation? Feel free to contact us. Our specialists are ready to assist you.

EN

EN

NL

NL PL

PL